Sonically Graded Soundboards

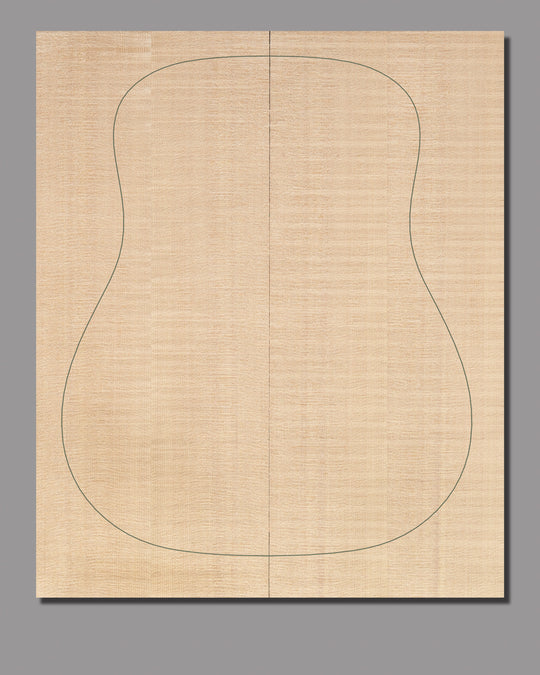

We carefully select every spruce log for our latest advancement in tonewood products – sonically graded soundboards. From splitting the logs into guitar blocks to bookmatching the grain, crucial decisions are made all along the way to ensure you’re building with the best guitar wood. These Lutz and Sitka spruce soundboards are pre-sorted in sonic grades of Low, Medium, and High density. Our stringent requirements ensure that every sonically graded soundboard consistently delivers superior sound, every time.

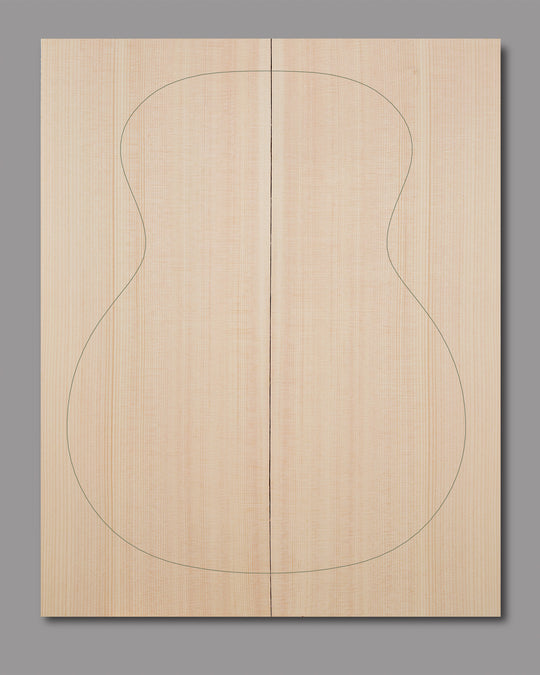

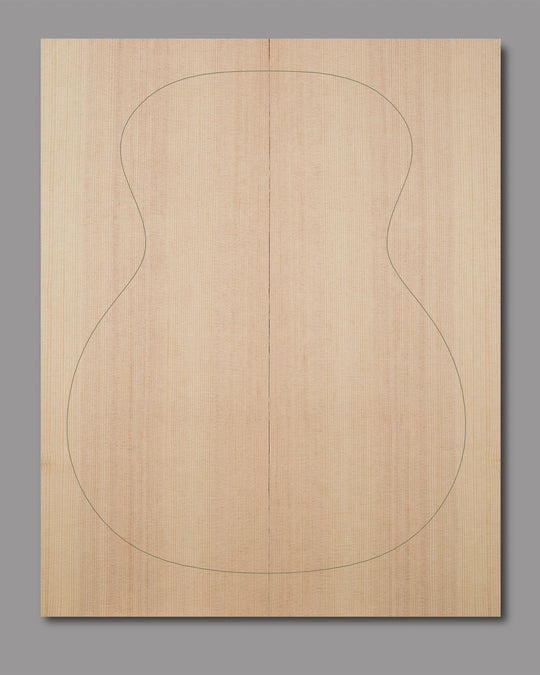

Not Actual Product.

Images are representative of what will be shipped.